Fine Thread Chipboard Screw – Precision Fastening for Durable Woodwork

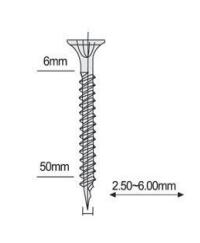

Product parameters

Type | Chipboard screw |

DIA | 8# |

Length | 16-100mm |

Color | Yellow |

Coating | Heat treatment, EG,phosphation |

APPLICATION

CERTIFICATION REPORT

Strict quality management system,ensure quality of raw quality

EXHIBITION

LOGOSTIC&PAYMENT

The Fine Thread Chipboard Screw is a specialized fastener designed for high-performance bonding in particleboard, MDF, and other engineered wood materials. Engineered with a unique fine thread pattern, these screws for chipboard ensure superior grip and stability, making them indispensable for furniture assembly, cabinetry, and DIY projects. Unlike standard wood screws, the chipboard screw is optimized to prevent splitting and ensure long-lasting structural integrity in low-density substrates.

Fine Thread Design for Enhanced Grip

The chipboard screw features tightly spaced threads that bite deeply into porous materials like particleboard. This design minimizes the risk of stripping or loosening, even under heavy loads.

Self-Tapping Tip for Easy Installation

Equipped with a sharp self-tapping point, screws for chipboard eliminate the need for pre-drilling in most applications, saving time and effort during assembly.

Corrosion-Resistant Coating

Many chipboard screws are coated with zinc or phosphate to resist rust, making them suitable for humid environments like kitchens, bathrooms, or outdoor furniture.

Compatibility with Power Tools

Designed for use with electric drills or impact drivers, screws for chipboard allow rapid installation without compromising precision.

Furniture Manufacturing

Assemble flat-pack furniture, bookshelves, or bed frames with chipboard screws for joints that withstand daily wear.

Secure drawer slides or cabinet hinges using screws for chipboard to prevent wobbling or misalignment.

Home Renovations

Install kitchen cabinets, countertops, or floating shelves with chipboard screws, ensuring a flush, professional finish.

Repair loose particleboard subfloors or wall panels using screws for chipboard for quick, reliable fixes.

DIY Craftsmanship

Build custom storage units, workbenches, or children’s toys with chipboard screws, ideal for lightweight yet sturdy constructions.

Attach decorative veneers or laminates to particleboard surfaces using screws for chipboard for seamless adhesion.

Commercial Use

Construct retail displays, office partitions, or exhibition stands with chipboard screws, balancing speed and durability.

Select the Correct Screw Size

Choose chipboard screws with lengths 1.5x the thickness of the material being joined. For example, use 30mm screws for 20mm-thick particleboard.

Tool Preparation

Fit a Phillips or Pozidriv bit into a drill/driver. Set the clutch to medium torque to avoid over-tightening screws for chipboard.

Driving the Screw

Position the chipboard screw perpendicular to the surface.

Apply steady pressure while driving to ensure the screw seats fully without stripping the material.

Post-Installation Check

Ensure the screws for chipboard sit flush with the surface. For load-bearing joints, add adhesive for extra strength.

Precision Engineering: The chipboard screw’s fine threads and sharp tip are tailored for low-density woods, reducing material damage.

Cost-Effective: Bulk packaging options make screws for chipboard affordable for both professionals and hobbyists.

Versatility: Suitable for indoor and outdoor projects, the chipboard screw adapts to diverse materials and environments.

Upgrade Your Fastening Solutions Today

Whether crafting bespoke furniture or tackling home improvements, the Fine Thread Chipboard Screw delivers unmatched reliability. Opt for screws for chipboard to achieve professional-grade results with minimal effort. Contact us for bulk orders or customized specifications tailored to your project needs.

FAQ

(1) Q:How many tons can be produced for per month?

A:We make over 10000 tons of various types of pneumatic nails for one month, here 5000 tons for export.

Sure,pls tell me your request,we will contact with you and make the design to you confirm.We have a professional packing factory to make it.

We make over 10000 tons of various types of pneumatic nails for one month, here 5000 tons for export.