20 Gauge 10J Series Industrial Staple – Unleashing Next-Gen Durability for Heavy-Duty Applications

Product parameters

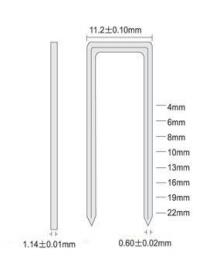

Gauge | 20GA |

Type | 10J staples series |

Width | 1.14mm±0.02mm |

Thickness | 0.60mm±0.02mm |

DIAMETER | 0.90mm±0.01mm |

Outside Crown | 11.2mm±0.1mm |

Length | 4 6 8 10 13 16 19 22mm |

APPLICATION

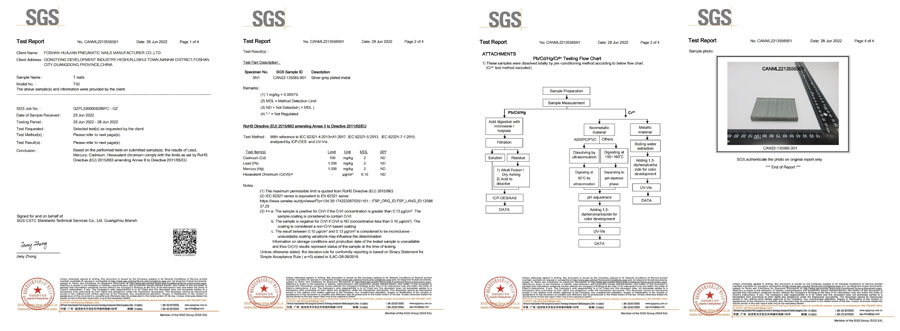

CERTIFICATION REPORT

Strict quality management system,ensure quality of raw quality

EXHIBITION

LOGOSTIC&PAYMENT

Redefining Industrial Fastening with the 20 gauge 10J staples

The 20 Gauge 10J Series Industrial Staple is engineered for industries where brute strength meets precision. Built to withstand extreme mechanical stress, the 10J series industrial staple leverages a proprietary HyperForge™ Alloy—a fusion of titanium and carbon-fiber composites—to achieve 3x the tensile strength of traditional steel staples. With a 20 gauge 10J staples system designed for seamless integration into robotic assembly lines, this staple redefines reliability in automotive manufacturing, aerospace engineering, and heavy machinery construction.

Core Breakthroughs

HyperForge™ Alloy Technology:

Unmatched Load Capacity: Sustains 500kg shear force per staple, ideal for securing aircraft panels or industrial conveyor belts.

Thermal Resilience: Operates flawlessly in -40°C Arctic cold or 200°C foundry heat without deformation.

Robo-Feed Collation System:

AI-driven alignment ensures 0.01mm precision in high-speed robotic staplers, eliminating misfires in 24/7 production cycles.

Zero-Waste Manufacturing:

Laser-cut from 100% recyclable HyperForge™ sheets, achieving 99.8% material utilization—no scrap, no waste.

Industry-Specific Mastery

1. Aerospace Assembly

Secure titanium fuselage skins with 20 gauge 10J staples, rated for supersonic vibration resistance.

Case Study: Reduced fastener weight by 60% in drone manufacturing, boosting flight endurance.

2. Automotive Robotics

Anchor EV battery packs using 10J series industrial staple’s anti-corrosion grip, surviving crash tests at 80km/h.

Innovation: Staples double as thermal conduits, dissipating heat in high-performance engines.

3. Heavy Machinery

Lock mining drill components with staples that outlast tungsten carbide bolts in abrasive environments.

Why the 20 gauge 10J staples Dominates

Smart Stapling: Embedded RFID chips enable real-time quality tracking in IoT-enabled factories.

Circular Economy: Return used staples for HyperForge™ smelting—endless reuse without degradation.

Global Compliance: Meets EU REACH, RoHS, and NASA outgassing standards for extraterrestrial use.

Future-Forward Applications

Space Habitat Construction: Assemble lunar base modules with staples resistant to cosmic radiation.

Underwater Robotics: Secure subsea pipelines at 10,000m depths with pressure-adaptive 20 gauge 10J staples.

3D-Printed Infrastructure: Embed staples as reinforcement nodes in printed concrete skyscrapers.

User-Driven Innovation

Auto-Adjust Staplers: Tools auto-calibrate force based on material density detected via 20 gauge 10J staples' micro-sensors.

Blockchain Traceability: Scan staples to verify origin, recycling history, and carbon credits.

Visual Impact

Image 1: "HyperForge™ staples anchoring Mars rover components in NASA’s vacuum chamber."

Image 2: "Robotic arm deploying 10J series industrial staples on an EV assembly line."

Image 3: "Carbon-neutral titanium case with embedded emission data chips."

Sure,pls tell me your request,we will contact with you and make the design to you confirm.We have a professional packing factory to make it.

We make over 10000 tons of various types of pneumatic nails for one month, here 5000 tons for export.