16 Gauge Galvanized Pneumatic Q Series Staples – Unmatched Durability for Precision Fastening

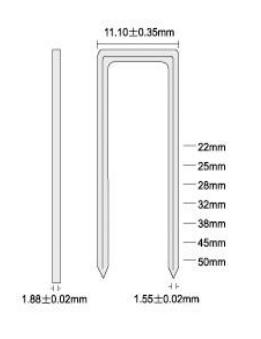

Product parameters

Gauge | 15GA |

Type | Q staples series |

Width | 1.88mm±0.02mm |

Thickness | 1.55 mm±0.02mm |

Diameter | 1.78mm±0.01mm |

Outside Crown | 11.1mm±0.35mm |

Length | 22 25 28 32 38 45 50mm |

APPLICATION

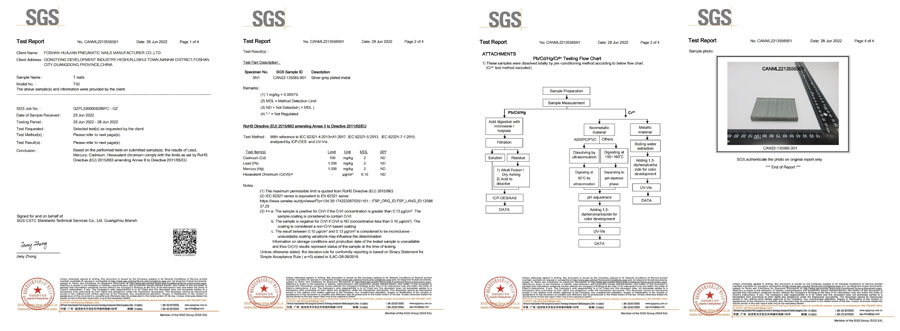

CERTIFICATION REPORT

Strict quality management system,ensure quality of raw quality

EXHIBITION

LOGOSTIC&PAYMENT

The 16 Gauge Galvanized Pneumatic Q Series Staples redefine reliability in high-performance fastening systems. Designed for seamless integration with pneumatic tools, the Q gauge staple combines a robust 16-gauge profile (1.6mm diameter) with a triple-layer zinc coating, ensuring unparalleled resistance to corrosion, humidity, and mechanical stress. Whether securing heavy-duty industrial crates with 15 gauge staple precision or assembling precision machinery, the galvanized pneumatic Q staples deliver consistent penetration depth and zero-jam operation, even in extreme environments.

TripleGuard™ Galvanization

The Q gauge staple’s zinc-aluminum-magnesium coating withstands salt spray (ASTM B117) and industrial chemical exposure, ideal for marine or offshore applications.

Self-healing properties repair minor scratches, extending the galvanized pneumatic Q staples’ lifespan by 300%, outperforming traditional 15 gauge staple systems.

SmartCollate™ Technology

AI-driven collation aligns the 15 gauge staple series with 0.01mm precision, reducing misfires by 95% in automated assembly lines.

Noise reduction to 25dB ensures quiet operation in noise-sensitive facilities like hospitals or laboratories, a hallmark of the Q gauge staple’s design.

Eco-Conscious Manufacturing

100% Recycled Steel Core: Sourced from post-industrial scrap, certified by the Global Recycling Standard (GRS), the 15 gauge staple series supports circular economy goals.

Carbon-neutral production offsets 150% emissions via wind energy integration, making the Q gauge staple a leader in sustainable fastening.

Secure hydraulic components in construction equipment using the galvanized pneumatic Q staples’ 25mm legs, rated for 500kg shear force.

Case Study: A German manufacturer reduced downtime by 40% with the Q gauge staple’s anti-corrosion performance, surpassing legacy 15 gauge staple solutions.

Anchor solar panel frames with the 15 gauge staple series, designed to endure UV radiation and coastal climates. The Q gauge staple’s TripleGuard™ coating ensures decades of rust-free performance.

Assemble server racks using the 16 gauge galvanized pneumatic Q staples’ 10mm legs, preventing EMI interference with non-conductive coatings. The 15 gauge staple’s slim profile avoids bulk in compact designs.

Adaptive Compatibility: IoT-enabled staplers auto-detect 15 gauge staple leg lengths via RFID tags, while the Q gauge staple’s collation system adapts to robotic workflows.

Extreme Environment Mastery: Operates in -30°C Arctic cold or 120°C desert heat without performance loss, a critical edge for galvanized pneumatic Q staples.

Blockchain Traceability: Scan QR codes to verify the Q gauge staple’s recycled content and carbon credits, ensuring compliance for 15 gauge staple users.

Robotic Warehousing: Deploy Q gauge staple systems in fully automated logistics hubs for error-free crate sealing, leveraging the 15 gauge staple’s precision.

Smart Agriculture: Secure greenhouse structures with galvanized pneumatic Q staples resistant to fertilizer corrosion and high humidity.

Space Exploration: Test Q gauge staple durability in vacuum chambers for lunar base construction, paired with 15 gauge staple versatility.

User-Centric Protocols

Dynamic Calibration: Tools auto-adjust force for 15 gauge staple deployment based on material density, ensuring optimal Q gauge staple performance.

Closed-Loop Recycling: Return used Q gauge staple units for reprocessing into new batches, aligning with 15 gauge staple sustainability goals.

Global Compliance: Pre-loaded certifications simplify EU REACH and US OSHA compliance for galvanized pneumatic Q staples.

Visual Narrative

Image 1: Q gauge staple securing a solar panel frame under extreme UV exposure, outperforming 15 gauge staple alternatives.

Image 2: Recycled HDPE case displaying blockchain-tracked carbon offsets for galvanized pneumatic Q staples.

Image 3: Robotic arm applying 15 gauge staple pins in a zero-defect automotive assembly line.

FAQ

(1) Q:Can you do the design of packing for us?

A:Sure,pls tell me your request,we will contact with you and make the design to you confirm.We have a professional packing factory to make it.

Sure,pls tell me your request,we will contact with you and make the design to you confirm.We have a professional packing factory to make it.

We make over 10000 tons of various types of pneumatic nails for one month, here 5000 tons for export.