- Home

- >

- Products

- >

- Brad Nails

- >

- 14 Gauge DT Brad Nails

- >

14 Gauge DT Brad Nails – Precision Engineering for Industrial and DIY Excellence

Product parameters

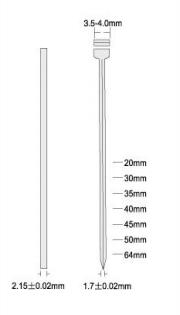

Gauge | 14GA |

Type | DT nails series |

Width | 2.15mm±0.02mm |

Thickness | 1.7mm±0.02mm |

DIAMETER | 2.02mm±0.01mm |

Head | 3.5-4.0mm |

Length | 20 30 35 40 45 50 64mm |

APPLICATION

14 Gauge Nails: High-Performance Material Design

The 14 gauge nails are precision-crafted from hardened carbon steel with a zinc-plated finish, ensuring corrosion resistance for the 14 gauge nails in both indoor and outdoor environments. The DT brad nails feature a slim 14-gauge profile (1.8-2.1mm diameter) optimized to minimize wood splitting, making the DT brad nails ideal for hardwoods, MDF, and engineered composites.

Pneumatic Nails Tool Compatibility

Designed for seamless integration with pneumatic nails guns, the DT brad nails utilize collated strips for rapid, jam-free feeding in high-speed applications. The pneumatic nails system, compatible with 18GA tools (e.g., DeWalt, Bostitch) at 70-100 PSI, ensures the 14 gauge nails deliver consistent penetration depth and reliability.

Micro-Head Precision for Aesthetic Excellence

The 14 gauge nails feature a micro-head design (1.8-1.9mm), leaving nearly invisible fastening marks—critical for high-end furniture, decorative trim, and automotive interiors where the DT brad nails’ aesthetics are paramount.

Construction & Roofing with Pneumatic Nails

Secure roofing felt, insulation boards, and house wrap effortlessly using the pneumatic nails system, leveraging the 14 gauge nails’ weather-resistant properties. The DT brad nails ensure long-term structural integrity in harsh climates.

Furniture Manufacturing Excellence

The DT brad nails excel in assembling cabinets, sofa frames, and drawer slides, providing robust joints without damaging delicate veneers. The 14 gauge nails are indispensable for high-volume production lines requiring the pneumatic nails tools’ speed.

Automotive & Marine Applications

Use the pneumatic nails tools to attach headliners, trim panels, or marine-grade upholstery, where the 14 gauge nails’ corrosion-resistant coating withstands saltwater environments. The DT brad nails are trusted for precision in marine interiors.

DIY & Craftsmanship Versatility

Ideal for DIY projects like picture frames or garden trellises, the DT brad nails offer precision with minimal surface marks. The 14 gauge nails paired with pneumatic nails tools streamline projects from start to finish.

Tool Setup & Calibration for Pneumatic Nails

Load the 14 gauge nails into an 18GA pneumatic nails gun and adjust the compressor to 70-100 PSI. Test the DT brad nails on scrap material to ensure depth settings prevent over-driving.

Fastening Techniques with DT Brad Nails

Position the DT brad nails at a 15-30° angle to the workpiece for maximum grip. Maintain consistent spacing (10-15cm) when using the 14 gauge nails to distribute structural loads evenly.

Maintenance of Pneumatic Nails Tools

Clean the pneumatic nails gun’s magazine weekly to remove debris. Lubricate moving parts monthly to ensure the DT brad nails feed smoothly and the 14 gauge nails perform reliably.

SGS Compliance for 14 Gauge Nails

The 14 gauge nails are backed by an SGS Report, validating compliance with RoHS standards. The DT brad nails undergo rigorous testing for tensile strength (≥450 N/mm²), ensuring the pneumatic nails system meets industrial demands.

ISO 9001 Certification for DT Brad Nails

Manufacturing processes for the DT brad nails adhere to ISO 9001 standards, guaranteeing dimensional accuracy. The 14 gauge nails’ zinc coating is tested for durability, while the pneumatic nails tools are certified for safety.

Cost Efficiency with Pneumatic Nails

The 14 gauge nails reduce labor costs by 20% compared to screws, ideal for high-volume lines. The DT brad nails’ collated design maximizes efficiency in pneumatic nails workflows.

Custom Solutions for DT Brad Nails

Offer branded packaging, custom lengths (18-64mm), or specialty coatings for the 14 gauge nails. The pneumatic nails system supports tailored solutions with a 1,000-box MOQ.

Global Logistics for 14 Gauge Nails

Produced in ISO-certified facilities, the DT brad nails and pneumatic nails tools are shipped globally, ensuring rapid delivery to meet project deadlines.

Conclusion

The 14 Gauge DT Brad Nails and pneumatic nails system redefine precision fastening, combining durability with user-centric design. Whether for construction, furniture crafting, or marine applications, the DT brad nails deliver unmatched reliability. Backed by certifications, the 14 gauge nails and pneumatic nails tools are the cornerstone of modern manufacturing.

Sure,pls tell me your request,we will contact with you and make the design to you confirm.We have a professional packing factory to make it.

We make over 10000 tons of various types of pneumatic nails for one month, here 5000 tons for export.