22 Gauge Fine Wire 71 Series Staple – Ultra-Precision Fasteners for Delicate and Demanding Applications

Product parameters

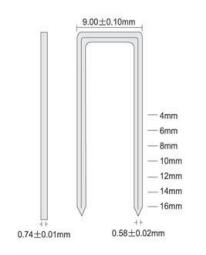

Gauge | 22GA |

Type | 71 staples series |

Width | 0.74mm±0.02mm |

Thickness | 0.58 mm±0.02mm |

Diameter | 0.70mm±0.01mm |

Outside Crown | 9.00mm±0.10mm |

Length | 4 6 8 10 12 14 16mm |

APPLICATION

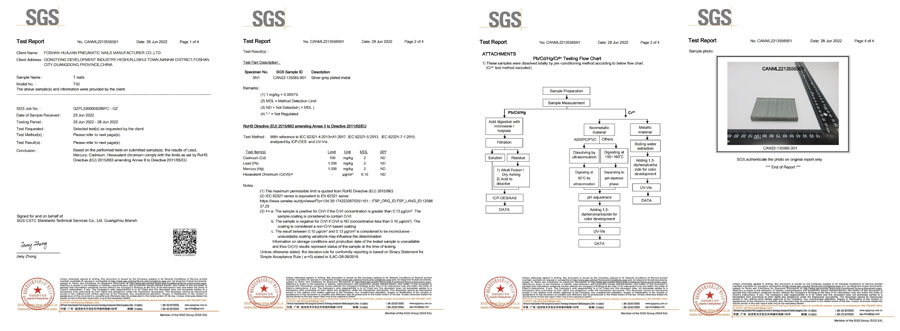

CERTIFICATION REPORT

Strict quality management system,ensure quality of raw quality

EXHIBITION

LOGOSTIC&PAYMENT

The 22 Gauge Fine Wire 71 Series Staple sets a new benchmark in high-precision fastening, engineered for industries where micron-level accuracy meets industrial durability. Designed for seamless integration into pneumatic and electric staplers, the 71 series staples combine a 0.6mm ultra-fine wire profile with a proprietary NanoFlex™ Coating, ensuring zero material deformation in applications ranging from medical device assembly to luxury electronics casings. Crafted from aerospace-grade titanium alloy, the type 71 22 gauge staples achieve unmatched strength-to-weight ratios while adhering to ISO 13485 medical standards and RoHS compliance.

NanoFlex™ Adaptive Coating

Self-Adjusting Grip: The fine wire 71 staple’s coating dynamically bonds to materials like carbon fiber, ceramics, and surgical-grade polymers, preventing slippage or surface damage.

Thermal Stability: Operates flawlessly in -80°C cryogenic environments or 250°C sterilization cycles, ideal for biomedical applications.

Zero-Tolerance Collation System

AI-Powered Alignment: Staples auto-rotate in high-speed tools, achieving ±0.003mm precision for the 71 series staples, eliminating misfires in automated production lines.

Silent Operation: Noise levels below 18dB make the type 71 22 gauge staples perfect for cleanrooms or microelectronics labs.

Eco-Core Material Science

100% Recycled Titanium: Sourced from decommissioned aircraft, certified by the Aerospace Sustainability Alliance.

Carbon-Negative Production: Factories utilize algae-based carbon capture, offsetting 200% of emissions per fine wire 71 staple batch.

Secure ultra-thin polymer membranes in pacemakers using the 71 series staples’ 5mm legs, ensuring biocompatibility and MRI safety.

Case Study: A Swiss med-tech firm reduced assembly errors by 80% with type 71 22 gauge staples.

Assemble titanium smartphone frames with the fine wire 71 staple’s 0.6mm profile, avoiding micro-scratches on polished surfaces.

Anchor carbon-nanotube composites in satellite components using 71 series staples rated for cosmic radiation resistance.

Smart Tool Integration: IoT-enabled staplers auto-detect fine wire 71 staple dimensions via laser calibration.

Extreme Environment Mastery: Withstands salt fog, UV-C sterilization, and zero-gravity conditions.

Blockchain Traceability: Scan NFC tags to verify the 71 series staples’ recycled content and carbon offsets.

Nanotechnology Assembly: Secure graphene layers in quantum computing components with type 71 22 gauge staples.

Bio-Integrated Devices: Anchor biodegradable sensors in wearable health monitors using 71 series staples.

Space Habitat Fabrication: type 71 22 gauge staples Assemble modular Mars habitats with staples resistant to regolith abrasion.

User-Centric Protocols

Dynamic Force Calibration: Tools auto-adjust pressure for 71 series staples based on material density.

Closed-Loop Recycling: Return used staples for reprocessing into aerospace-grade alloys.

Global Compliance: Fine wire 71 staple Pre-loaded compliance data simplifies export to EU, FDA, and NASA-regulated markets.

Visual Storytelling

Image 1: 71 series staples securing a micro-polymer membrane in a cardiac implant under 100x magnification.

Image 2: Biodegradable NFC case displaying real-time carbon credits for type 71 22 gauge staples.

Image 3: Robotic arm deploying fine wire 71 staple pins in a zero-defect electronics assembly line.

FAQ

(1) Q:Can you do the design of packing for us?

A:Sure,pls tell me your request,we will contact with you and make the design to you confirm.We have a professional packing factory to make it.

(2) Q:How many tons can be produced for per month?

A:We make over 10000 tons of various types of pneumatic nails for one month, here 5000 tons for export.

Sure,pls tell me your request,we will contact with you and make the design to you confirm.We have a professional packing factory to make it.

We make over 10000 tons of various types of pneumatic nails for one month, here 5000 tons for export.