What Are Brad Nails For? Exploring Uses, Benefits, and Industry Trends

Title: What Are Brad Nails For? Exploring Uses, Benefits, and Industry Trends

Brad nails have become a cornerstone in modern construction and woodworking, but many buyers still ask: What are brad nails for? These slender, lightweight fasteners are designed for precision tasks where traditional nails or screws might split materials or leave visible marks. Let’s dive into the latest developments in the brad nail industry and why these tools are indispensable for trim work, woodworking projects, and beyond.

Understanding Brad Nails: Design and Purpose

Brad nails are defined by their thin gauge (typically 18-gauge) and small heads, making them ideal for delicate woodworking projects and trim work. Unlike bulkier nails, brad nails excel in securing baseboards, crown molding, and lightweight materials without splitting wood. Their discreet design allows them to blend seamlessly into surfaces, reducing the need for extensive sanding or filling—a critical advantage for trim work requiring flawless finishes.

In the fast-evolving fastener market, trim work remains the primary application for brad nails. Manufacturers now produce anti-corrosion coated brad nails, enhancing durability for both indoor woodworking projects and outdoor installations like garden furniture or pergolas.

Why Brad Nails Dominate Woodworking Projects

For woodworking projects, brad nails strike the perfect balance between strength and subtlety. Their thin gauge minimizes damage to fragile materials like hardwood veneers or composite boards—a key reason why woodworking projects increasingly rely on these fasteners. Cabinetmakers and furniture builders use brad nails to assemble joints or attach decorative elements, ensuring structural integrity without compromising visual appeal.

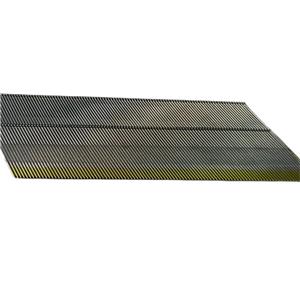

Recent innovations include collated brad nails for pneumatic nail guns, boosting efficiency in high-volume trim work installations. Industry reports highlight a 12% annual growth in demand for brad nails, driven by the surge in home renovation and custom woodworking projects.

Key Advantages of Using Brad Nails

Reduced Material Splitting: The thin gauge of brad nails distributes pressure evenly, protecting softwoods and engineered materials in woodworking projects.

Easy Concealment: Small holes left by brad nails can be quickly filled, speeding up finishing work for trim work or furniture assembly.

Versatility: Compatible with manual hammers and power tools, brad nails adapt to both small-scale repairs and large-scale trim work installations.

Suppliers are emphasizing eco-friendly options, such as recycled-steel brad nails, to align with sustainability trends in woodworking projects and construction.

Emerging Trends in the Brad Nail Industry

As woodworking projects grow more intricate and trim work standards rise, specialized brad nails are gaining traction. Stainless-steel variants dominate humid climates, while angled brad nails improve accessibility in tight spaces—essential for complex trim work designs. E-commerce platforms now offer bulk purchasing options, catering to contractors and hobbyists focused on woodworking projects or renovation tasks.

Modular construction’s rise has positioned brad nails as critical components for assembling prefabricated units, particularly in trim work-heavy sectors like hospitality and retail. Industry leaders predict a 15% increase in brad nail exports by 2025, with North America and Europe driving demand for woodworking projects and architectural detailing.

Choosing the Right Brad Nails for Your Project

When selecting brad nails for trim work or woodworking projects, consider length, gauge, and material:

Trim work: 1.5-inch 18-gauge brad nails for baseboards and moldings

Woodworking projects: 2-inch nails for thicker hardwoods or cabinetry

Always test brad nails on scrap wood to ensure compatibility with tools and materials.

Conclusion: The Future of Brad Nails

Brad nails are essential for achieving flawless results in woodworking projects, trim work, and modern construction. With advancements in corrosion resistance and tool compatibility, these fasteners continue redefining precision across industries. Whether crafting custom furniture or executing intricate trim work, understanding what brad nails are for unlocks unmatched efficiency and craftsmanship.

Keywords: brad nails, trim work, woodworking projects